Water Cooling Channels Decrease 3D Printed Mold Tool's Cycle Time by 50% - Fortify

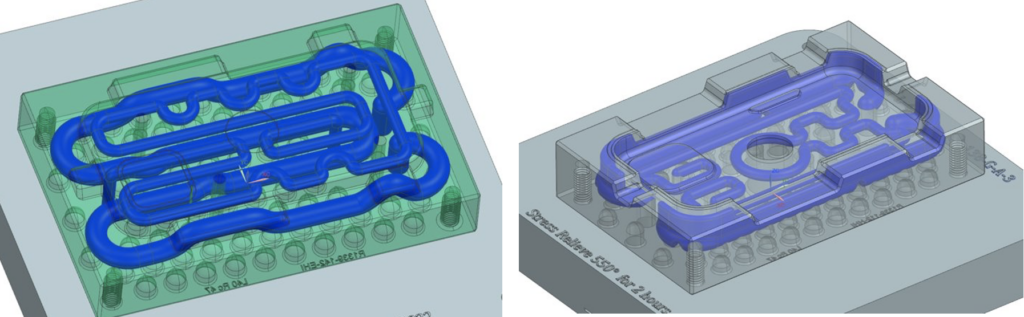

Fortify and PTC worked together to prove out if water cooling channels designed into the 3D printed mold tool could help reduce cycle time.

Do Water Cooling Channels Decrease Cycle Time for 3D Printed Mold Tools?

Technology Roundup: Moldmaking Technologies You'll See in the 2021 Sourcing Guide

Multiscale Porosity in Compressible Cryogenically 3D Printed Gels for Bone Tissue Engineering

Processes, Free Full-Text

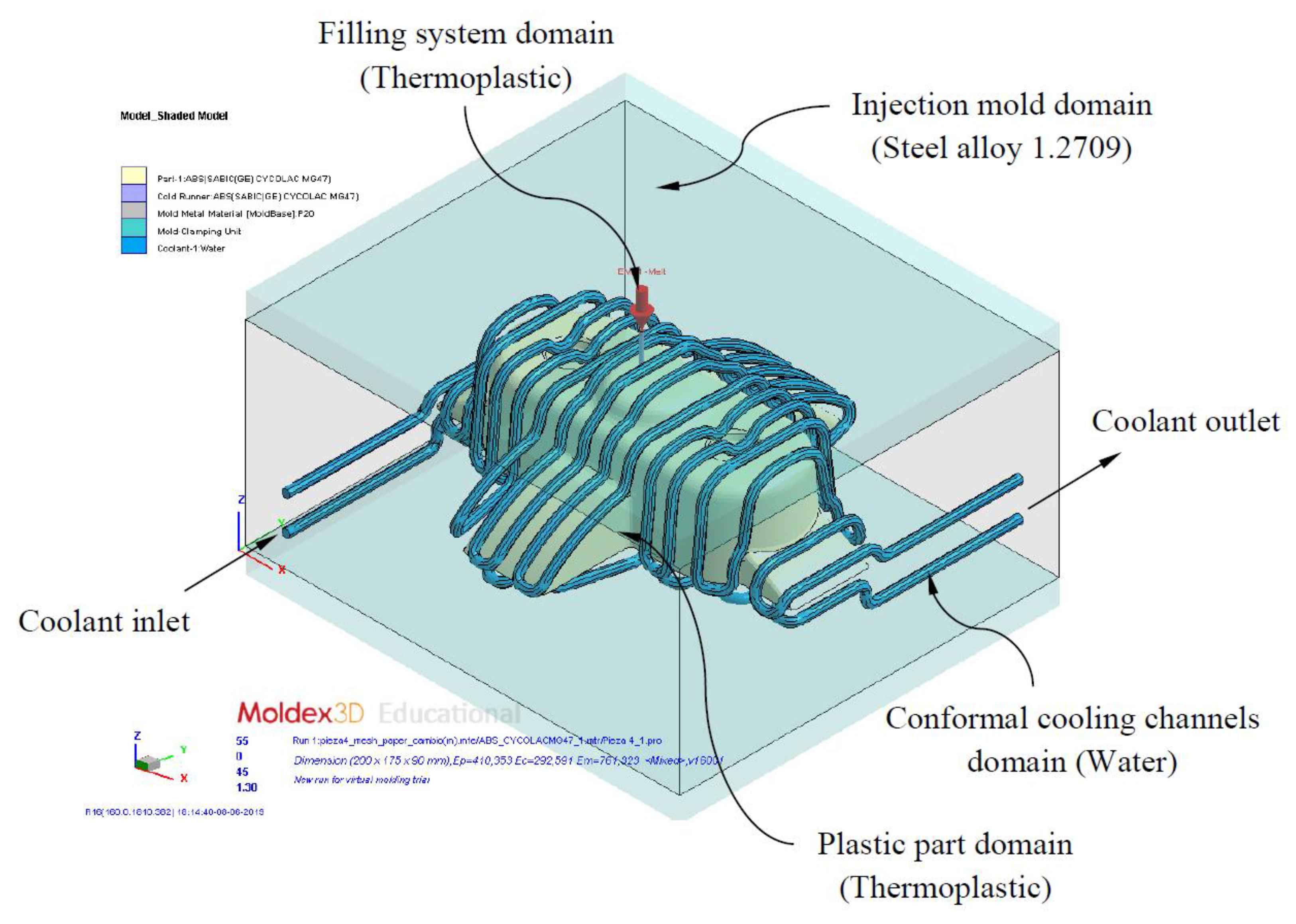

Conformal Cooling: Higher-Quality Parts, Faster Injection Molding Cycle Times - SyBridge Technologies

Benjamin MacDonald on LinkedIn: #molddesign #moldmaking #additivemanufacturing #molds

Benjamin MacDonald on LinkedIn: #molddesign #moldmaking #additivemanufacturing #molds

Additive manufacturing–assisted conformal cooling channels in mold manufacturing processes - Mahesh S Shinde, Kishor M Ashtankar, 2017

3D PRINTED MOLD TOOLING - Fortify

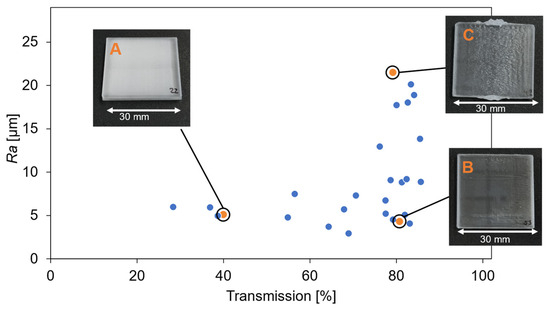

Polymers, Free Full-Text

A review on the tooling technologies for composites manufacturing of aerospace structures: materials, structures and processes - ScienceDirect

:strip_icc()/pic7389885.jpg)